What ‘Pending Remote Fulfillment’ Means for Your Online Orders: A Clear Breakdown

Pending remote fulfillment status on your order can raise questions when you’re waiting for your products to reach your customers. At IWS, we know that understanding order statuses helps you make informed decisions for your business. This guide breaks down what pending remote fulfillment means, why it happens, and how it affects your shipments.

Understanding ‘Pending Remote Fulfillment’

When your order shows “pending remote fulfillment,” it indicates your products have been received in our system and are being processed at a location different from the main fulfillment center.

What Does ‘Pending Remote Fulfillment’ Mean?

Pending remote fulfillment refers to an order status that appears after your order has been validated but before the products have been physically picked, packed, and prepared for shipping from an external fulfillment location. This happens when your products are stored at a warehouse location other than the primary facility.

For businesses shipping health and beauty products, lightweight consumer goods, or beverages, this status is a normal part of the fulfillment process. Speed and accuracy over long-term storage are which are two characteristics of fulfillment centers that distinguish them from traditional warehouses. This operational focus means your order is being coordinated through our network of strategically placed fulfillment centers to optimize shipping times and costs for your customers.

Importance of Order Status Clarity

Clear order status communication is key to maintaining your business operations and customer satisfaction. When you see “status: pending remote fulfillment” in your dashboard, this transparency allows you to:

- Provide accurate delivery estimates to your customers

- Plan your inventory replenishment accordingly

- Make informed decisions about stock levels

- Track your products throughout the fulfillment journey

For small to mid-sized brands shipping hundreds of orders monthly, having this visibility can make a significant difference in customer satisfaction rates. At IWS, we provide real-time status updates through our client portal so you always know exactly where your products are in the fulfillment process.

Why Your Order Shows ‘Pending Remote Fulfillment’

Understanding the reasons behind this status helps you better manage your business operations and customer expectations.

Strategic Inventory Distribution

When your order displays pending remote fulfillment, it’s often because we’re utilizing our network of fulfillment centers to provide you with the most cost-effective shipping solution. This strategic approach offers several benefits:

- Regional Proximity: Fulfilling orders from locations closer to your customers reduces transit times and shipping costs

- Specialized Handling: Certain products (like temperature-sensitive items) may be stored at facilities with specialized equipment

- Balanced Workload: Distributing orders across multiple facilities helps maintain processing speed during high-volume periods

For example, if your business ships beauty products to customers nationwide, we might fulfill West Coast orders from our California facility while East Coast orders are processed from our New York location, all managed seamlessly through our central system.

Seasonal Demand Management

During peak seasons like holiday shopping periods, remote fulfillment becomes an important tool to maintain service quality. When order volumes spike:

- Primary facilities may reach capacity, triggering automatic routing to secondary locations

- Special promotions can create sudden demand surges that require distributed processing

- Product-specific rushes (like seasonal beverages) might be directed to specialized handling facilities

Our systems are designed to automatically balance workloads across all facilities, maintaining consistent processing times even during your busiest seasons. This approach prevents the bottlenecks that can occur when relying on a single fulfillment location.

Influence of Third-Party Logistics (3PL)

Understanding how third-party logistics providers impact the pending remote fulfillment process helps explain why this status appears in your order tracking.

How 3PLs Manage Remote Fulfillment

As a 3PL provider, IWS creates a bridge between your business and your customers through our national network of fulfillment centers. When orders enter pending remote fulfillment status, we’re coordinating several critical aspects:

- Cross-Network Inventory Visibility: Our warehouse management system tracks your products across multiple facilities

- Order Routing Logic: Orders are assigned to facilities based on product location, destination address, and current processing capacity

- Multi-Carrier Shipping Integration: We select the optimal shipping method based on your requirements and customer location

This centralized management of distributed operations is what makes remote fulfillment possible, allowing your products to ship from the most advantageous location without requiring you to manage relationships with multiple warehouses.

Benefits of 3PL-Powered Remote Fulfillment

Working with a 3PL like IWS for your remote fulfillment needs offers distinct advantages:

- Expanded Geographic Reach: Access to fulfillment centers in multiple regions without capital investment

- Carrier Rate Negotiation: Better shipping rates through our consolidated volume across all clients

- Scalable Capacity: Ability to handle volume fluctuations without fixed overhead costs

- Technology Integration: Advanced systems that connect with your e-commerce platform and provide real-time visibility

- Specialized Expertise: 3PLs like IWS excel at small parcel fulfillment for direct-to-consumer brands, with dedicated processes that optimize packaging, reduce dimensional weight charges, and ensure prompt carrier pickups for even the smallest orders in your product catalog.

By partnering with a 3PL for remote fulfillment, you transform what could be a complex logistics challenge into a competitive advantage, letting you focus on product development and marketing while we handle the operational details of getting orders to your customers.

How Orders Move Through Remote Fulfillment

Understanding the workflow helps you track your orders and set accurate expectations for your customers.

The Order Processing Journey

When your order enters the remote fulfillment stage, it follows a structured path:

- Order Receipt: Your order is received through our integration with your e-commerce platform

- Assignment: Our system assigns the order to the optimal fulfillment location based on product availability and shipping destination

- Picking: Warehouse staff select your products from inventory locations

- Quality Check: Each item is verified against order specifications

- Packing: Products are packaged according to your requirements with any custom inserts or branded materials

- Shipping Preparation: Labels are created and carriers are assigned based on your shipping rules

- Dispatch: Products leave our facility and enter the carrier’s network

This process typically takes 1-2 business days from receipt to dispatch for standard orders. At IWS, we maintain an average accuracy rate of 99.7% through our rigorous quality control protocols.

Technology Behind Remote Fulfillment

The “pending remote fulfillment” status is made possible by our integrated technology systems that connect all aspects of the fulfillment process:

- Inventory Management System: Tracks real-time stock levels across all locations

- Order Management Platform: Intelligently routes orders to appropriate facilities

- Warehouse Management System: Guides picking, packing, and quality control processes

- Shipping Integration: Automatically selects the most cost-effective carrier options

- Client Portal: Provides you with visibility into your order status and inventory levels

This technology infrastructure allows us to maintain high service levels while giving you complete transparency into your order fulfillment operations. Through your personalized dashboard at invwhs.com, you can monitor each order’s status as it moves through the fulfillment process.

What to Expect During Remote Fulfillment

Knowing what to expect when your orders show “pending remote fulfillment” helps you manage both your operations and customer communications.

Typical Timelines

Remote fulfillment may add a small amount of processing time compared to standard fulfillment, but the overall impact on delivery is often minimal:

| Order Type | Processing Time | Notes |

| Standard Orders | 1-2 business days | Most health and beauty, lightweight consumer goods |

| Custom Packaging | 2-3 business days | Orders requiring special inserts or gift wrapping |

| Temperature-Controlled | 1-2 business days | Beverages and sensitive products |

| High-Volume Orders | 2-3 business days | Bulk shipments of 100+ identical items |

| Orders shipped NDA | Same business day | When received before 12 PM local time, ensuring delivery within 24 hours to most continental US locations |

These timelines reflect normal operations outside of peak holiday seasons, when additional processing time may be required. Our client success team will communicate any anticipated delays during high-volume periods.

Communication Best Practices

When your orders are in remote fulfillment status, following these communication practices helps maintain customer satisfaction:

- Update your shipping policy page to reflect accurate processing times

- Set automated post-purchase emails to acknowledge orders with realistic timeframes

- Use our status API to provide real-time updates on your website or app

- Train customer service staff to explain pending remote fulfillment if customers inquire

Many IWS clients find that proactive communication about order status leads to higher customer satisfaction scores and fewer support inquiries.

Optimizing Your Experience with Remote Fulfillment

You can take several actions to make the most of remote fulfillment capabilities.

Inventory Planning Strategies

Strategic inventory management can help you maximize the benefits of remote fulfillment:

- Regional Distribution: For businesses with nationwide customer bases, distributing inventory across multiple fulfillment centers can reduce shipping times and costs

- Seasonal Preparation: Communicate expected sales spikes to your fulfillment partner in advance

- Forecast Sharing: Provide monthly projections to help us prepare adequate resources

By planning inventory levels strategically across our network, your orders can ship from optimal locations, minimizing both cost and transit time to your customers.

Working with Your Fulfillment Partner

To get the most from remote fulfillment capabilities:

- Schedule regular check-ins with your dedicated account manager

- Review fulfillment analytics through your client portal to identify patterns

- Communicate product changes or special handling requirements in advance

- Share feedback on carrier performance to help optimize shipping options

At IWS, we view ourselves as an extension of your team. Your account manager is available to answer questions about pending remote fulfillment status and help you optimize your fulfillment strategy.

Pending Remote Fulfillment FAQs

How long does pending fulfillment take?

Pending fulfillment typically takes 1 to 5 days, depending on inventory availability, order volume, and warehouse processing speed. Delays may occur due to stock shortages, high demand, or operational issues.

What causes delays in fulfillment?

Delays in fulfillment occur due to inventory shortages, supply chain disruptions, high order volume, staffing issues, or carrier delays. Poor warehouse management and inefficient order processing also slow fulfillment times.

What is the difference between fulfillment and shipping?

Fulfillment includes order processing, picking, packing, and shipping, while shipping refers only to the transportation of goods to the customer. Fulfillment is a broader process, ensuring orders are correctly prepared before shipment.

What is the difference between fulfillment and delivery?

Fulfillment involves order processing, packing, and shipping, while delivery refers to the final step of transporting the order to the customer’s location. Fulfillment ensures accurate order preparation, while delivery completes the transaction.

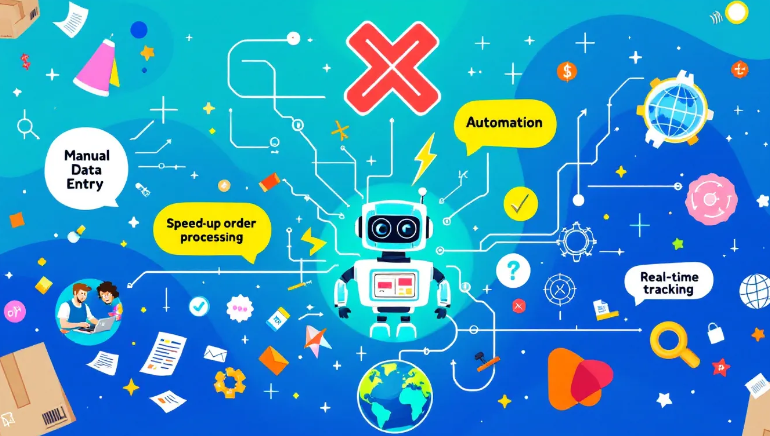

How can I speed up fulfillment?

Speed up fulfillment by automating order processing, optimizing warehouse layout, maintaining accurate inventory, partnering with efficient carriers, and using multiple fulfillment centers. Reducing manual tasks and improving supply chain coordination minimizes delays.

Conclusion

Understanding what “pending remote fulfillment” means gives you better control over your order fulfillment operations. This status simply indicates that your orders are being processed through our distributed network of fulfillment centers to provide optimal service to your customers.

By working closely with your fulfillment partner and maintaining clear communication with your customers, you can turn this fulfillment approach into a competitive advantage for your business. Remote fulfillment allows you to offer faster, more cost-effective shipping while maintaining the order accuracy your customers expect.

If you have questions about pending remote fulfillment or want to learn how IWS can help streamline your order processing, contact our team at invwhs.com/contact for a personalized consultation.

The Essential Guide to Distribution and Fulfillment Center Operations

Are your products reaching customers efficiently, or is your supply chain clogging up? To know the difference between direct distribution and fulfillment services, you need to understand their purposes.

Distribution centers move bulk products to retailers, fulfillment centers handle individual customer orders. This difference affects your operational costs, delivery time and customer satisfaction. For growing brands shipping 300+ orders a month, choosing the right logistics approach can mean the difference between growing and chaos.

Distribution Centers vs Fulfillment Centers

Both distribution and fulfillment centers are critical in modern supply chains but operate under different models to achieve different goals.

What is a Distribution Center?

A distribution center is designed to receive, store and redistribute large quantities of products to other businesses, retail locations or secondary distribution points. These centers connect manufacturers with retailers and wholesalers through bulk product movement.

Distribution centers process large shipments and are located in strategic places that minimize transportation costs while having access to major shipping routes. Their operations revolve around space utilization and inventory tracking systems that optimize the movement of palletized goods.

Functions of a Distribution Center

The main focus of a distribution center is the flow of products through the supply chain at scale:

- Receiving and Storage: Distribution centers receive large shipments from manufacturers, usually full truckloads or container quantities. Products are stored in palletized units not individual items.

- Cross-Docking and Redistribution: Many centers move products from inbound to outbound vehicles with minimal storage time, keeping products moving to retailers and wholesalers.

- Advanced Transfer Methods: Many distribution centers utilize the benefits of cross docking to minimize storage time and handling costs. This technique allows products to move directly from inbound to outbound transportation, dramatically reducing warehouse dwell time and accelerating the flow of goods through the supply chain.

- Transportation Optimization: Strategic locations near transportation hubs help minimize lead times while maximizing delivery efficiency, crucial for brands in competitive retail.

What is a Fulfillment Center?

A fulfillment center focuses on processing individual customer orders for direct-to-consumer businesses. While distribution centers connect businesses to businesses, fulfillment centers connect businesses to end consumers through accurate and fast order processing.

Two key characteristics of fulfillment centers are speed and accuracy over long term storage. They process high volumes of small orders, making them perfect for e-commerce businesses. Unlike distribution centers, fulfillment center operations prioritize inventory turnover over storage.

Functions of a Fulfillment Center

The specialized nature of fulfillment centers is evident in their core functions:

- Order Processing: When a customer clicks “buy” integrated systems send that information to the fulfillment center instantly and trigger the fulfillment workflow.

- Picking, Packing, and Shipping: Staff or automated systems locate products, package them for individual shipment and prepare them for delivery with emphasis on accuracy and presentation.

- Returns Management: Fulfillment centers handle return processing, inspection, restocking and refunds – a critical service for customer satisfaction.

- Specialized Handling: Modern fulfillment centers excel at small parcel fulfillment for direct-to-consumer brands, with expertise in packaging individual items safely and cost-effectively regardless of size or fragility. This specialization is particularly valuable for businesses with diverse product catalogs or those selling items requiring special handling.

Distribution and Fulfillment Services Comparison

Understanding the operational differences between these two logistics models helps businesses make informed decisions about their supply chain.

Direct Distribution vs Fulfillment Services

Direct distribution and fulfillment services are two different ways to get products to their destination. The key differences lie in the level of control, operational involvement and target recipients.

In direct distribution businesses have more control over the entire process from warehouse operations to transportation logistics. This is typically company owned or contracted facilities moving products to retail locations or other businesses. The focus is on bulk movement and inventory positioning.

Fulfillment services on the other hand specialize in individual customer orders, often as a third-party provider. These services excel in processing many small orders not few large shipments. For e-commerce businesses partnering with a fulfillment service like Innovative Warehouse Solutions allows them to focus on product development and marketing while leaving the operational logistics to experts.

Operational and Logistical Differences

The operational structures of these two models reveal significant contrasts in how they function:

| Aspect | Direct Distribution | Fulfillment Services |

| Control | Complete control over logistics operations including staffing, equipment, and transportation | Operations managed by third-party experts with limited direct oversight |

| Flexibility | More standardized operations year-round with less ability to scale quickly | Easily scales during peak seasons without requiring additional infrastructure investment |

| Technology Focus | Emphasis on inventory tracking and route optimization for bulk shipments | Priority on order management systems integrated with e-commerce platforms and real-time consumer updates |

| Order Types | Primarily handles large, bulk shipments to businesses | Specializes in processing numerous small individual orders |

| Geographic Reach | Limited by company-owned facility locations | Access to established network of fulfillment centers for broader coverage |

Advantages and Disadvantages

Each approach offers distinct benefits and challenges that businesses should consider when developing their logistics strategy.

| Direct Distribution | Fulfillment Services | |

| Advantages | Direct distribution provides greater control over brand presentation and customer experience. Companies can potentially achieve higher margins by eliminating third-party costs. This model also offers direct access to distribution data and insights, along with the ability to customize operations for specific product requirements. | Fulfillment services require reduced capital expenditure through transparent, pay-for-what-you-use pricing models. Businesses gain access to established logistics networks and expertise without building their own. This approach offers the ability to scale operations quickly during growth periods, while allowing companies to focus resources on creating products and generating sales rather than managing logistics. |

| Disadvantages | This approach requires significant capital investment in facilities, equipment, and personnel. It involves complex logistics management requiring specialized expertise that may distract from core business growth. Direct distribution offers less flexibility during seasonal fluctuations and creates geographic limitations based on facility locations. | Fulfillment services provide less direct control over fulfillment operations, which may create consistency challenges. Some providers lack transparency in their pricing and performance metrics. Companies may face challenges with accommodating complex product requirements unless they choose a partner experienced in their specific industry. |

Future of Distribution and Fulfillment

The landscape is changing driven by technological innovation and consumer expectations. Understanding the trends helps businesses prepare for what’s next.

Technology

Technology is impacting both distribution and fulfillment:

- Automation and Robotics: Warehouse automation is changing picking, packing and sorting processes. Mobile robots and automated storage systems increase efficiency and reduce labor costs, allowing industry leaders to maintain accuracy even during peak volume.

- Artificial Intelligence and Predictive Analytics: Smart systems optimize inventory levels, anticipate demand fluctuations and identify potential supply chain disruptions before they happen. This proactive approach keeps inventory balanced and prevents stockouts.

- Integration: Modern fulfillment centers offer seamless integration with e-commerce platforms like Shopify, WooCommerce and Amazon. These connections eliminate manual order processing and provide real-time inventory visibility across all sales channels.

- Last Mile: New approaches to final delivery include micro-fulfillment centers in urban areas and strategic regional placement to reduce shipping costs and delivery times. These solutions address the most expensive part of the delivery process.

- Order Status Transparency: Modern fulfillment systems provide customers with detailed tracking information throughout the delivery process. Understanding terms like pending remote fulfillment helps both businesses and consumers track order status accurately and predict delivery timeframes, leading to improved customer communication and satisfaction.

Sustainability

Environmental concerns are reshaping logistics across both distribution and fulfillment:

- Green Facility Design: Modern logistics facilities are incorporating sustainable features like energy efficient systems and water conservation measures. These reduce environmental impact and often lower operational costs.2. Packaging: Sustainable packaging reduces waste and protects products during transit. Right-sized packaging, biodegradable materials and reusable containers make for more eco-friendly fulfillment.

- Transportation: Route optimization, vehicle efficiency and load consolidation reduce carbon emissions in product movement. Good for the planet and the bottom line.

- Circular Supply Chains: Advanced returns processing creates circular supply chains where products and materials stay in circulation through multiple lifecycles. This requires sophisticated tracking and processing.

Direct Distribution and Fulfillment Services FAQs

What is the difference between direct distribution and indirect distribution?

The main difference between direct and indirect distribution is intermediaries. Direct distribution sells products straight to consumers without third parties, while indirect distribution uses wholesalers, retailers, or distributors to reach customers. Direct distribution offers more control and higher profits, but indirect distribution provides wider market reach.

What is the difference between fulfillment and logistics?

Fulfillment focuses on processing and delivering customer orders, including storage, packing, and shipping. Logistics involves broader supply chain management, covering transportation, warehousing, and inventory control. Fulfillment is a part of logistics, ensuring efficient order handling and customer satisfaction.

What is the difference between a fulfillment center and a warehouse?

A fulfillment center processes and ships customer orders quickly, handling inventory storage, picking, packing, and shipping. A warehouse primarily stores goods for long periods without actively handling order processing. Fulfillment centers focus on speed and efficiency, while warehouses prioritize bulk storage.

What is the difference between fulfillment service and dropshipping?

A fulfillment service stores, packs, and ships products for businesses that own inventory. Dropshipping allows retailers to sell products without holding inventory, with suppliers shipping orders directly to customers. Fulfillment services require inventory investment, while dropshipping eliminates upfront stock costs.

What is the difference between direct to consumer and dropshipping?

Direct-to-consumer (DTC) brands sell products directly to customers, managing inventory and fulfillment. Dropshipping relies on third-party suppliers to handle inventory and shipping. DTC offers better brand control and higher margins, while dropshipping minimizes risk but reduces control over product quality and delivery.

Conclusion

The decision between direct distribution and fulfillment services is a strategic one with big implications for your business growth. Distribution centers are great at moving bulk quantities to businesses, fulfillment centers are expert at processing individual orders for end consumers.

For most businesses shipping 300+ orders a month, the best approach depends on your specific needs, resources and growth stage. Many successful companies use hybrid models, direct distribution for certain channels and fulfillment services for e-commerce.

As technology evolves and consumer expectations change, both distribution and fulfillment must adapt. The winning logistics strategies will be automated, transparent and customer centric.

Ready to transform your logistics? Contact Innovative Warehouse Solutions today to talk about how our transparent, customer focused fulfillment services can help your business grow and simplify operations.

How Cross Docking Can Enhance Your Supply Chain Performance

Is your supply chain slowing down your business growth? Cross-docking benefits could be the answer you’re looking for.

This logistics strategy eliminates storage by moving products directly from incoming to outgoing vehicles and cuts handling time and costs. While traditional warehousing ties up your capital in inventory, cross-docking keeps products moving through your supply chain, helps you deliver faster to customers, and has leaner operations.

What is Cross Docking

Let’s break down what cross docking is and how it differs from traditional warehousing methods so you can understand its impact on your supply chain.

What is Cross Docking?

Cross docking is a logistics practice where products from a supplier or manufacturing plant are delivered directly to a customer or retail chain with minimal to no handling or storage time. Instead of storing products in a warehouse, products are unloaded from incoming trucks and loaded onto outgoing trucks, often within 24 hours.

Unlike traditional warehousing, which focuses on storage, cross docking creates a smooth flow of products across the supply chain. In a traditional warehouse, goods sit in storage for days, weeks, or even months before shipping to their final destination. With cross docking, products sit in the distribution center just long enough to be sorted and organized for outbound transportation.

Main Benefits of Cross Docking

One of the biggest benefits of cross-docking is cost reduction. By minimizing or eliminating storage requirements, businesses can reduce warehouse space needs, cutting costs associated with facility maintenance, utilities, and storage equipment. This turns fixed costs into variable costs that scale with your business.

Cross docking also speeds up delivery times. With products in transit and handling for less time, goods get from manufacturer to customer much faster. This is especially valuable for perishable or time-sensitive products that need to get to customers quickly to maintain quality or meet market demands.

Cross Docking vs Traditional Warehousing

Traditional warehousing follows a receive-store-pick-pack-ship model where goods are stored for varying periods. Cross docking follows a streamlined receive-sort-ship process within a shorter timeframe. This difference impacts everything from facility design to staffing and technology needs.

For supply chain managers looking to identify differences between direct distribution and fulfillment services, understanding these operational distinctions is crucial for determining which model best suits specific product categories and business requirements.

Cross docking is ideal for high-volume, fast-moving products with predictable demand. For example, retail chains use cross-docking for core products that sell consistently. Traditional warehousing is better suited for products with unpredictable demand patterns, seasonal products, or products that require special handling or storage conditions.

Cross Docking’s Impact on Supply Chain Performance

Implementing cross-docking can change your supply chain operations in many ways. Here’s how this strategy can improve efficiency and reduce costs across your logistics network.

Speed and Efficiency

Cross docking simplifies the flow of goods by removing unnecessary steps between suppliers and customers. Products move through the supply chain without the delays associated with storage, picking, and packing. This direct transfer approach can reduce handling time by up to 60% compared to traditional warehousing methods.

The reduction in touchpoints has ripple effects throughout the supply chain. Every time a product is handled, there’s a chance of damage, misplacement, or administrative errors. By minimizing these interactions, cross docking not only speeds up delivery but improves accuracy and reduces product damage rates.

Many major retailers have seen significant performance improvements after implementing cross-docking. For example, some retail chains have reported 15-20% faster delivery times and a 25% increase in inventory turns after moving selected product lines to cross-docking operations.

Cost Savings

The cost benefits of cross-docking go beyond simple warehousing cost reduction. By eliminating storage, businesses can operate with smaller facilities focused on sorting and transfer rather than large warehousing. This can reduce facility costs by 25-30% compared to traditional warehousing operations. When combined with techniques like what is zone skipping, businesses can further optimize their logistics network to minimize transit zones and significantly reduce shipping expenses across regional boundaries.

Labor costs are also reduced through cross-docking. With fewer picking, packing, and inventory management tasks, staffing needs decrease while productivity per employee increases. Transportation costs can be optimized through better consolidation and route planning, especially when cross-docking facilities are located to serve multiple markets.

A medium-sized consumer goods company working with specialized logistics partners like Innovative Warehouse Solutions reported annual savings of $250,000 after implementing cross docking for their fast-moving product lines. These savings were mainly from reduced warehousing costs, lower inventory carrying costs, and better transportation utilization.

Customer Satisfaction

In today’s market, customer expectations for fast delivery continue to rise. Cross docking helps businesses meet these demands by reducingthe time products spend in the supply chain. When done correctly cross docking can cut delivery times by 1-3 days compared to traditional warehousing methods, giving you a significant competitive advantage.

The ability to respond quickly to market demand is another customer satisfaction driver. Cross docking facilities can process large volumes of products quickly, allowing businesses to respond faster to sudden demand spikes or distribute new product launches. This responsiveness builds customer trust and loyalty.

Companies that have implemented cross-docking have seen measurable improvements in customer satisfaction metrics. According to data from retailers that have cross-dock buildings, on-time delivery rates improved by 12% and order accuracy by 8% after implementing cross-docking for suitable product lines.

Implementing Cross-Docking in Your Supply Chain

Successful cross-docking integration into your logistics operations requires planning and the right resources. Let’s look at what you need to make cross-docking work for your business.

Infrastructure and Technology

Effective cross-docking needs a specific facility design. The ideal cross-dock building has a rectangular, or I shape with multiple dock doors on opposite sides—inbound shipments come in one side, and outbound shipments go out the other. The facility should have minimal interior obstructions to allow for efficient product movement and sorting.

Technology plays a big part in managing cross-docking operations. A WMS that supports cross-docking functionality is essential for coordinating the movement of goods. This system needs to provide real-time visibility into incoming and outgoing shipments, automate sorting decisions, and assign dock doors.

Modern cross-docking operations are incorporating technologies like barcode scanning, RFID tracking, and automated sorting systems to reduce handling time and improve accuracy. Some advanced systems even use predictive analytics to predict incoming shipment volumes and adjust staffing and resource allocation accordingly.

Strategic Planning and Execution

Implementing cross-docking starts with identifying which products are best suited for this approach. Ideal candidates are high-volume items with predictable demand, products with short shelf life, and pre-packaged items that require minimal handling. Start with a limited product selection to test processes before rolling out to other suitable items.

Cross docking needs to align with your overall supply chain strategy. This includes working with suppliers to ensure product quality and delivery schedules. Many companies have strict vendor compliance programs that specify packaging requirements, labeling standards, and delivery windows to support cross-docking operations.

When evaluating cross-docking rates and adoption timing, consider starting with a pilot program on a single product category or specific high-volume customers. This allows you to refine processes, train staff, and identify potential issues before full-scale implementation.

Partnering with 3PLs for Cross Docking

For many businesses, partnering with a 3PL is the fastest way to implement cross-docking. 3PLs already have the infrastructure, technology, and operational expertise to do cross-docking. This partnership approach eliminates the need for capital investment in facilities and systems.

3PLs that specialize in cross-docking can provide the flexibility and scalability that’s hard to achieve on your own. During peak seasons or promotional periods you can increase your cross docking volume without capacity constraints. During slower periods, you can scale back without maintaining unused infrastructure.

When selecting a 3PL partner for cross docking services, evaluate their experience with similar products and industries. Ask for specific information on their cross dock vs rear load facilities, as the facility design makes a big difference to operational efficiency. Many businesses find that partners who excel at small parcel fulfillment can offer more comprehensive solutions that integrate cross docking with last-mile delivery needs. Other key factors are geographic coverage, technology capabilities and established carrier relationships.

Cross Docking Advantages FAQs

What are the three main types of cross-docking?

The three main types of cross-docking are manufacturing cross-docking, retail cross-docking, and opportunistic cross-docking. Manufacturing cross-docking consolidates raw materials for production. Retail cross-docking moves products directly to stores. Opportunistic cross-docking transfers incoming shipments to outbound trucks without storage.

What is the difference between cross-docking and transloading?

The main difference between cross-docking and transloading is storage and handling. Cross-docking transfers goods directly from inbound to outbound transport with minimal storage time. Transloading involves temporary storage and transferring goods between different transportation modes, such as from rail to truck.

What type of product is most suitable for cross-docking?

Perishable goods, high-demand retail items, and pre-packaged consumer products are most suitable for cross-docking. These items require fast movement through the supply chain to prevent spoilage, meet demand, or reduce storage costs.

What are the risks of cross-docking?

The risks of cross-docking include inventory mismanagement, delays, damaged goods, and high dependency on logistics coordination. Without precise timing and tracking, errors can disrupt operations and increase costs.

What are the challenges of cross-docking?

The main challenges of cross-docking include supply chain synchronization, infrastructure investment, and reliable supplier coordination. Efficient cross-docking requires real-time inventory tracking, skilled labor, and advanced warehouse management systems to prevent bottlenecks.

Conclusion

Cross docking benefits continue to make this logistics strategy attractive for businesses looking to optimise their supply chain. By removing unnecessary storage and handling you can achieve significant cost savings and speed to market and customer satisfaction. The cross docking vs traditional warehousing comparison clearly shows that for the right products and market conditions cross docking is the better option.

As supply chains get more complex and customer demand for fast delivery continues to rise cross docking is a practical solution that answers both operational and market demands. Whether implemented in-house or with a 3PL partner cross docking can turn your logistics into a competitive advantage.

Ready to Try Cross Docking for Your Business?

At Innovative Warehouse Solutions, we specialize in helping businesses implement effective cross docking strategies that deliver measurable supply chain improvement. Our transparent pricing means you’ll always know what you’re paying for, no hidden fees or surprises.

Ready to find out more about cross docking for your business? Contact us today for a consultation. Our logistics experts will help you determine if cross docking is right for your products and develop a customised implementation plan that fits your business goals.

Cargo vs Shipment: Key Differences & Practical Examples Explained

Confused about the difference between cargo and shipment in your logistics operations? This isn’t just a matter of semantics—it affects how you communicate with partners, plan your supply chain, and manage your documentation.

Both terms relate to goods being moved but serve different purposes in the logistics world. Understanding the shipment vs cargo distinction helps you speak the language of logistics professionals and make better decisions about your business’s transport needs.

Understanding Cargo vs Shipment

From documentation to planning, knowing when to use “cargo” versus “shipment” impacts your whole logistics operation.

Definitions

Cargo refers to the physical goods or merchandise being transported, typically in bulk. It’s the actual items, products, or materials being moved from one location to another. Cargo is about the physical items themselves, regardless of how they’re packaged for transport. When logistics professionals talk about cargo, they’re talking about the actual physical goods—whether raw materials, finished products, or components.

Shipment describes the process of moving goods or the organized unit of goods being sent from one place to another. A shipment includes not just the cargo itself but also the documentation, packaging, and transportation method. When you track a shipment, you’re following the journey of a specific consignment that has been organized for delivery.

Key Differences

The table below highlights the essential distinctions between cargo and shipment:

| Aspect | Cargo | Shipment |

| Definition | The physical goods or merchandise being transported | The process of transporting goods or the organized unit being sent |

| Focus | The actual items themselves | The journey and logistics of moving items |

| Usage Example | “The cargo was damaged during handling” | “The shipment was delayed due to weather” |

| Documentation | Described in packing lists and manifests | Tracked with waybills, BOLs, and tracking numbers |

| Insurance | Cargo insurance covers the goods themselves | Shipment insurance may cover the entire process |

| Responsibility | Typically, the concern of warehousing staff | Managed by logistics and transportation teams |

These distinctions matter significantly when communicating with logistics partners, filing insurance claims, or preparing customs documentation.

Why It Matters

Using the right terminology ensures clear communication with logistics partners, carriers, and customs officials. Confusion about whether you’re talking about the physical goods (cargo) or the transport unit and process (shipment) can lead to errors in documentation, insurance gaps, or compliance issues.

For businesses using fulfillment services, this affects how you communicate your needs and understand the services provided. When a logistics provider talks about handling your cargo, they’re referring to the physical management of your goods. When they mention processing your shipments, they’re talking about moving your goods from origin to destination.

Modes of Transport for Cargo

Each transport mode has its own advantages that can impact your supply chain efficiency and costs.

Cargo Ships

Maritime transport is the backbone of global trade, moving around 90% of the world’s cargo by volume. Cargo ships are the most efficient for bulk and non-time-sensitive goods. These vessels, especially container ships, can move massive amounts of cargo across oceans at relatively low cost per unit.

The efficiency of maritime cargo transport comes from economies of scale—a single large container ship can carry over 20,000 TEU (twenty-foot equivalent units). This capacity makes sea transport the most cost-effective option for international trade, especially for heavy or bulky items where air freight would be too expensive.

Cargo Planes

When speed is more important than cost, air cargo is the fastest option. Air transport is ideal for high-value, time-sensitive, or perishable cargo that justifies the premium cost. Electronics, pharmaceuticals, fashion items, and emergency supplies often travel as air cargo.

For businesses with urgent delivery needs, specialized NDA shipping services provide guaranteed next-day delivery, further reducing transit times for critical items while maintaining careful handling standards throughout the logistics process.

While more expensive than sea transport, air cargo has its advantages: dramatically reduced transit times, higher security, and access to regions without seaports. For businesses where time-to-market is critical, the speed of air cargo can offset its higher cost through reduced inventory holding and faster cash conversion cycles.

Freight Trucks and Trains

Land-based cargo transport through trucks and trains is the middle mile in most supply chains. Trucks offer flexibility and direct point-to-point delivery, while trains excel at moving large cargo volumes over long distances.

Intermodal transport—combining multiple modes such as truck to rail or truck to ship—optimizes the whole cargo journey. This allows businesses to leverage the strengths of each transport mode, creating more resilient and cost-effective supply chains. For example, cargo might travel by sea across oceans, then transfer to trains for long-distance land transport and finally complete the final delivery by truck.

Types of Shipments

Understanding different shipment types helps you choose the most cost effective and efficient option for your business.

Full-Truckload or Full-Container Load (FTL/FCL)

FTL/FCL shipments involve booking an entire truck or container for your goods. This is ideal when shipping volumes that can fill or nearly fill a container or truck. The main benefits include reduced handling of goods, lower risk of damage and usually faster transit times as the vehicle goes directly to the destination without multiple stops.

From a cost perspective, FTL/FCL shipments often have better per-unit shipping rates when shipping large volumes. Additionally, these shipments minimize the risk of cross-contamination or mixing with other shippers’ goods. For businesses with consistent high-volume shipping needs, setting up regular FTL/FCL shipments means predictable logistics costs and timelines.

Less-than-Truckload or Less-than-Container Load (LTL/LCL)

LTL/LCL shipments allow businesses to move smaller quantities of goods without paying for unused space. With this approach, multiple shippers share the cost of a single container or truck, each paying only for the space their cargo occupies. This makes sense for businesses with smaller shipping volumes or irregular shipping schedules.

While LTL/LCL shipments are usually more expensive per cubic foot than full loads, they eliminate the need to wait until you have enough goods to fill an entire container. For small to mid-sized businesses, this means you can ship products as needed rather than based on container capacity. This approach works particularly well when combined with effective small parcel fulfillment strategies for your direct-to-consumer orders.

Innovative Warehouse Solutions specializes in optimizing LTL/LCL shipments for growing businesses, helping them balance cost efficiency with delivery time.

Choosing the Right Logistics Partner

The difference between logistical headaches and smooth operations often comes down to choosing the right partner for your cargo and shipment needs.

Importance of a Reliable Partner

A strategic logistics partner does more than just move cargo from A to B—they become an extension of your business. The right partner has expertise in navigating complex shipping regulations, optimizing transport routes, and managing documentation properly. This expertise directly impacts your bottom line through reduced shipping costs, fewer delays, and higher customer satisfaction.

When evaluating potential logistics partners, look beyond basic pricing to assess their on-time delivery record, communication transparency, technology capabilities, and problem-solving skills. The most valuable logistics relationships are built on consistent performance and proactive communication, especially when things go wrong.

Modern businesses often sell through multiple channels simultaneously—from e-commerce websites to marketplaces and physical retail locations. In these cases, partnering with providers offering omnichannel 3PL services becomes essential for maintaining consistent inventory records and fulfillment standards across all sales channels. This integrated approach ensures that cargo handling and shipment processes remain synchronized regardless of where customer orders originate.

Innovative Warehouse Solutions Advantage

Innovative Warehouse Solutions offers a customer-centric approach that sets us apart in the 3PL industry for businesses looking to optimize their cargo management and shipment processes. Unlike big impersonal logistics providers, IWS focuses on creating tailored solutions for small to mid-sized businesses shipping at least 300 orders a month.

The IWS advantage is in combining technology with customer service. Their warehouse management system has real-time visibility into inventory and shipments and their transparent pricing model eliminates the hidden fees common in logistics services. This technology and transparency allow businesses to make data-driven decisions and have predictable operational costs.

Shipment vs Cargo FAQs

What is the difference between cargo and freight shipping?

Cargo refers to goods transported via air, sea, or land, typically in bulk. Freight shipping specifically refers to commercial transportation of goods, usually by trucks, trains, ships, or planes. Cargo is a broader term, while freight shipping is a method of transporting cargo.

What is the difference between shipment and transportation?

Shipment refers to a specific set of goods being transported, while transportation is the overall process of moving goods from one place to another. Shipment is a unit of transported goods, whereas transportation includes vehicles, routes, and logistics.

What are the three types of cargo?

The three main types of cargo are general cargo, bulk cargo, and liquid cargo. General cargo includes packaged goods like electronics. Bulk cargo consists of unpackaged goods like coal or grain. Liquid cargo includes fluids like oil or chemicals.

What is cargo in shipping terms?

In shipping, cargo refers to goods or merchandise transported by air, sea, or land. It includes containerized, bulk, and breakbulk shipments but typically excludes passenger luggage.

What is the legal definition of shipment?

Legally, a shipment is a batch of goods transported under a single bill of lading or contract. It represents one delivery of goods from a seller to a buyer through an agreed transportation method.

Summary

Understanding the difference between cargo and shipment goes beyond semantics – it’s how you structure your entire logistics operation. Cargo is the physical goods themselves, shipments is the process of moving those goods from origin to destination. This matters for insurance coverage to customs documentation.

As you develop your logistics strategy, choosing the right modes of transport and shipment types makes a big difference in cost and customer satisfaction. Whether you’re shipping full containers across the ocean or managing less-than-truckload shipments domestically, working with an experienced logistics provider helps you navigate the complexities of modern supply chains.

Looking to optimize your cargo management and shipment processes? Contact Innovative Warehouse Solutions for a consultation. We’re customer-focused and transparent in our pricing.

Zone Skipping: A Smart Strategy to Cut Shipping Costs

Are your shipping costs eating into your profits? Many businesses don’t realize they’re paying premium rates for inefficient shipping routes. Zone skipping provides a solution that not only cuts costs but also speeds up delivery to your customers—a win-win strategy for businesses looking to optimize their logistics operations.

What is Zone Skipping?

Understanding zone skipping is essential for businesses looking to gain a competitive edge in logistics management and cost control.

Definition and Overview

Zone skipping is a logistics strategy where businesses consolidate multiple packages heading to the same general region and transport them together to a distribution center closer to the final destination. From there, packages enter the local delivery network, effectively “skipping” several zones in the carrier’s network.

Carrier networks like USPS, UPS, and FedEx divide the country into shipping zones based on distance from the origin point. With costs increasing as packages cross more zones, consolidating shipments allows businesses to bypass these intermediate zones by moving products in bulk to a hub closer to the final destinations.

Importance in E-commerce

For e-commerce businesses, zone skipping has become increasingly valuable as customer expectations for fast, affordable shipping continue to rise. According to industry data, businesses implementing these strategies can reduce shipping costs by 15-25% while improving delivery times by 1-2 days on average.

Companies that rely heavily on small parcel shipping find zone skipping particularly valuable, as it offers economies of scale that might otherwise only be available to larger operations with extensive carrier contracts.

How Does Zone Skipping Work?

The mechanics of zone skipping involve strategic consolidation and transportation planning to maximize efficiency and cost savings.

Process Overview

The zone skipping process follows several key steps:

- Package Consolidation: Businesses gather multiple packages heading to similar destinations.

- Bulk Transportation: These consolidated shipments travel together via truck, rail, or air freight to a distribution center closer to the final destinations.

- Local Sortation: At the destination hub, packages are sorted for local delivery.

- Last-Mile Delivery: Carriers complete the final delivery to customers through their local networks.

For example, a retailer with many West Coast customers might consolidate all those packages and ship them directly to a California distribution center, bypassing intermediate sorting facilities.

The economics work when the cost of bulk transportation plus local delivery fees is less than sending each package through the entire carrier network individually, typically requiring a minimum volume threshold of 300 orders monthly.

Key Components

Successful implementation relies on several critical elements:

- Data Analytics: Shipping volume analysis helps identify optimal consolidation opportunities and destination hubs. Software tools track package destinations to find patterns worth targeting.

- Transportation Partners: Strong relationships with freight carriers who can handle bulk shipments between major hubs are essential. These partnerships often include negotiated rates based on consistent volume.

- Distribution Network: Access to strategically located distribution centers allows businesses to position inventory closer to customers. These centers serve as consolidation and deconsolidation points.

- Inventory Management: Effective inventory forecasting ensures sufficient stock is available at each distribution point to meet customer demands.

Businesses implementing zone skipping should also explore the benefits of cross docking to further enhance efficiency by eliminating unnecessary storage and reducing handling time between inbound and outbound shipments.

Examples of Zone Skipping

This strategy works across various business models:

E-commerce Retail: A clothing retailer with a warehouse in Chicago might consolidate all packages heading to the Southwest, shipping them in bulk to a Phoenix distribution center for local delivery throughout Arizona, New Mexico, and Nevada.

Subscription Services: A meal kit company can maintain freshness by shipping consolidated pallets of boxes to regional distribution centers, where they enter local carrier networks for next-day delivery.

Manufacturing: A parts supplier can combine multiple small orders heading to automotive plants in the Southeast, shipping them as a single freight load to Atlanta for distribution throughout the region.

Benefits of Zone Skipping

Zone skipping offers multiple advantages that directly impact your bottom line and customer satisfaction levels.

Cost Reduction

The primary benefit is significant cost savings:

- Lower Per-Package Rates: Consolidating shipments gives businesses access to bulk shipping rates that are substantially lower than individual package rates. Savings typically range from 15-40%, depending on volume and distance.

- Reduced Zone Charges: Since packages enter the carrier network closer to their final destination, they cross fewer zones, directly reducing zone-based fees.

- Optimized Fuel Surcharges: Consolidated shipments require less fuel per package compared to individual routing, creating additional savings when fuel surcharges apply.

- Volume Discounts: Consistent large-volume shipments to specific regions can qualify for additional carrier discounts that aren’t available for individual packages.

For a mid-sized e-commerce business shipping consistently, these savings can translate to tens of thousands of dollars annually in reduced shipping costs.

Time Efficiency

Beyond cost savings, time efficiency creates competitive advantages:

- Faster Transit Times: By bypassing intermediate sorting facilities, packages reach customers 1-2 days faster on average. This improvement can transform standard shipping into an experience that rivals premium options.

- More Predictable Delivery: Fewer touchpoints in the shipping process mean fewer opportunities for delays, resulting in more consistent delivery times that businesses can reliably promise to customers.

- Extended Order Cutoff Times: With faster transit times, businesses can offer later daily order cutoffs while still meeting the same delivery timeframes.

These time efficiencies allow businesses to meet rising customer expectations without raising prices.

Risk Mitigation

Zone skipping also helps reduce various logistics risks:

- Fewer Touchpoints: With packages changing hands fewer times between origin and destination, there’s less opportunity for damage, loss, or misrouting. This directly translates to fewer customer service issues and replacement costs.

- Simplified Tracking: Consolidated shipments are easier to monitor until they reach the destination hub, giving businesses better visibility and control over their products in transit.

- Weather and Disruption Buffers: Using multiple regional distribution points creates flexibility during disruptions. If one region experiences delays, businesses can reroute through alternative hubs.

Companies implementing zone skipping report a 30% average reduction in damaged or lost packages, creating additional savings beyond the direct shipping cost reductions.

Is Zone Skipping Right for Your Business?

Not every business benefits equally from zone skipping strategies—understanding your shipping profile is crucial to determining its value for your operation.

Assessing Suitability

Consider these factors when evaluating zone skipping for your business:

- Shipping Volume: Zone skipping typically requires meeting minimum volume thresholds to a specific region to be cost-effective. Businesses shipping fewer orders may not realize sufficient savings.

- Geographic Distribution: Analyze your shipping data to identify concentrated delivery areas. This strategy works best when a significant percentage of your shipments go to specific regions rather than being evenly distributed nationwide.

- Product Characteristics: Consider your products’ weight, dimensions, and value. Higher-value items with moderate weight often benefit most from zone skipping due to the balance of shipping costs and protection benefits.

- Delivery Time Requirements: If your business competes on delivery speed, zone skipping can be particularly valuable in meeting customer expectations without premium shipping costs.

A thorough cost-benefit analysis should compare current shipping expenses against projected costs with zone skipping, including any additional handling or transportation requirements.

Implementation Steps

If zone skipping appears viable for your business, follow these steps for implementation:

- Data Analysis: Review 6-12 months of shipping data to identify volume patterns and potential consolidation opportunities. Focus on regions receiving the highest percentage of your shipments.

- Partner Selection: Research and select transportation partners for bulk shipping between your fulfillment center and destination hubs. Consider both cost and reliability in your evaluation.

- Distribution Network: Identify destination hubs in regions where you have significant delivery volume. These could be carrier facilities or third-party logistics providers like Innovative Warehouse Solutions that specialize in regional distribution with a focus on customer service excellence.

- Pilot Program: Start with a single high-volume region to test processes and confirm savings before expanding. This allows you to refine procedures with minimal risk.

- Technology Integration: Ensure your order management and shipping systems can properly route orders for zone skipping. This may require updates to your software integrations.

- Staff Training: Train fulfillment staff on new procedures for consolidating and preparing zone-skipped shipments, which differ from standard package handling.

For companies planning implementation during peak season, reviewing black friday logistics tips can provide valuable insights on managing high-volume consolidation without compromising delivery timelines during the most demanding retail period of the year.

Most businesses can implement a basic zone skipping program within 60-90 days, with ongoing optimization continuing as more data becomes available.

Customer Communication

Effective communication about shipping improvements offers marketing advantages:

- Clear Expectations: Update delivery time estimates on your website to reflect faster shipping times made possible through your improved logistics strategy.

- Shipping Options: Consider creating new shipping tiers that take advantage of these efficiencies, such as “Fast Standard Shipping” that promises delivery times previously only possible with expedited services.

- Marketing Advantage: Promote improved shipping speeds in marketing materials. Customers care about results—faster delivery at reasonable costs—not the logistics methods that make them possible.

- Tracking Updates: Ensure customers receive appropriate tracking information once packages enter the local delivery network from the regional hub.

By communicating these improvements effectively, businesses can turn logistics efficiency into a competitive advantage that builds customer loyalty.

Zone Skipping FAQs

What is zone pricing in logistics?

Zone pricing in logistics is a shipping rate structure based on distance from the origin to the destination. Carriers divide regions into zones, with costs increasing as the delivery zone gets farther from the shipping point.

What does zone mean when shipping?

In shipping, a zone refers to a geographic area used to determine delivery rates. Carriers assign zones based on the distance between the sender and recipient, affecting shipping costs and transit times.

How to calculate shipping zone?

Calculate a shipping zone by measuring the distance between the origin ZIP code and the destination ZIP code. Carriers use predefined zone maps to determine which zone a shipment falls into, influencing pricing and delivery speed.

What are zones in FedEx?

FedEx zones are geographic areas used to calculate shipping costs. Zones range from Zone 1 (local deliveries) to higher zones for long-distance shipments. The greater the zone number, the higher the shipping cost.

What is Zone 1 in logistics?

Zone 1 in logistics refers to the closest delivery area to the shipping origin. It typically covers local or nearby destinations, offering the fastest and most cost-effective shipping rates.

Conclusion

Zone skipping presents a strategic approach to shipping that can significantly reduce costs while improving delivery times. For businesses shipping sufficient volume to specific regions, the benefits extend beyond direct cost savings to include faster deliveries, reduced damage rates, and improved customer satisfaction.

As e-commerce continues to grow and customer expectations for fast, affordable shipping rise, efficient logistics strategies become increasingly important competitive differentiators. Businesses that analyze their shipping patterns and implement targeted zone skipping programs can create both operational efficiencies and marketing advantages.

At Innovative Warehouse Solutions, we prioritize transparent, customer-centric service that stands out in the 3PL industry. Our strategically located facilities and commitment to accuracy make us an ideal partner for implementing zone skipping strategies tailored to your specific business needs.

Ready to explore how zone skipping could benefit your business? Contact Innovative Warehouse Solutions for a consultation on how our fulfillment expertise and software solutions can help you implement cost-saving logistics strategies while providing the real-time, personalized support your business deserves.

Top 7 Order Fulfillment Mistakes and How to Avoid Them

Order fulfillment mistakes can hurt your business. In this article, we cover the top 7 errors businesses make and how to avoid them. By spotting these issues early, you can improve your process and keep customers happy.

The Significance of Efficient Order Fulfillment

Efficient order fulfillment directly impacts business success by ensuring prompt and flawless delivery. Effective order management system helps maintain a stellar reputation and achieve profitability. Streamlined processes enable businesses to meet customer expectations for fast and transparent delivery, significantly influencing overall satisfaction.

For businesses shipping lightweight items directly to consumers, implementing effective small parcel shipping solutions can dramatically reduce delivery times and costs while minimizing handling errors that lead to customer dissatisfaction.

Conversely, poor order fulfillment often leads to damaged items and lost customers, severely affecting business growth. The consequences of inefficient order fulfillment processes are far-reaching, including customer dissatisfaction, increased returns, and negative reviews. Customers today have high expectations for quick and incident-free delivery, and failing to meet these expectations can erode loyalty.

Efficiently locating, packaging, and shipping items in a timely manner remains a significant challenge. Coordinated efforts across various fulfillment aspects are necessary. Prioritizing accuracy and speed ensures customers receive their orders as expected, fostering trust and repeat business.

Order fulfillment isn’t solely about speed; accuracy and reliability throughout the entire fulfillment process are equally important. Each step, from inventory management to shipping, must be optimized to prevent errors and delays. Focusing on these aspects enhances supply chain efficiency and ensures customer satisfaction.

Common Order Fulfillment Mistakes Businesses Make

Minimizing common order fulfillment mistakes is vital for online business growth. These errors often arise from inefficient processes, leading to more mistakes and decreased customer satisfaction. As businesses expand, the complexity of order fulfillment increases, making mistakes more likely.

We’ve identified seven common ecommerce fulfillment mistakes that businesses frequently make. Understanding these pitfalls and implementing strategies to avoid them helps streamline fulfillment operations and enhance overall efficiency.

Let’s explore these mistakes in detail.

Poor Inventory Management

Inaccurate inventory management causes stockouts or overstocks, leading to delays and increased fulfillment costs. Effective inventory control is crucial for timely and accurate order fulfillment. Stock distortion can cost businesses $1.1 trillion globally, highlighting the severe financial impact of poor inventory practices.

A robust inventory management system accurately tracks inventory levels and prevents discrepancies. Automated inventory management software provides real-time visibility, crucial for avoiding stockouts and overstocks. Real-time tracking significantly improves inventory accuracy and helps mitigate fulfillment errors.

Inaccuracies in inventory management often stem from manual data entry errors, causing discrepancies in stock levels. Ineffective demand forecasting can result in both overstocking and understocking, leading to inefficiencies. Integrating advanced technology and conducting regular audits are essential for maintaining accurate inventory levels and ensuring efficient order fulfillment.

Packing Errors

Packing errors can lead to damaged products and unhappy customers. Incorrect packing results in costly returns, disappointed customers, and poor reviews.

Ill-fitting packing materials, untrained staff, and careless handling contribute to packing errors. Low-quality packaging can damage products during transit, negatively impacting customer satisfaction. Using high-quality materials and providing proper staff training can mitigate these issues and enhance the packing process.

Shipping Delays

Inefficient order processing significantly contributes to slow shipping, leading to customer dissatisfaction. Slow shipping can result in negative reviews and decreased sales, with 84% of purchasers unlikely to shop with a brand again after a negative delivery experience. Consumers expect quick delivery and may shop elsewhere if delivery is delayed.

Shipping delays often result from inefficient order processing, inventory inaccuracies, and poor warehouse management. Other factors include customer location, carrier choice, and customs requirements. Partnering with reputable carriers and ensuring proper packaging quality can minimize shipping delays.

The right technology and shipping carrier systems, especially during high-volume seasons, enhance shipping efficiency. Optimizing workflows and automating packing can help reduce delays. Integrating with shipping carriers automates label generation, booking shipments, and tracking packages, improving the shipping process and the fulfillment process.

Ineffective Communication with Customers

Poor communication impacts logistics operations, brand image, customer loyalty, cash flow, and overall business goals. Ineffective communication increases customer inquiries and dissatisfaction. If not addressed proactively, customers may feel ignored and frustrated.

Implementing tools like a Knowledge Base and live chat features significantly improves customer communication. Providing clear and timely updates on order status enhances customer satisfaction and reduces inquiries. Effective communication ensures customers feel valued and informed throughout the delivery process.

High Shipping Costs

Determining shipping charges that are both competitive and profitable is often challenging. Ineffective box sizing increases shipping costs and the chances of damage. Over-packing can result in higher material costs, shipping expenses, and environmental waste.

Overlooking shipping costs can erode profits. To mitigate this, businesses should negotiate better shipping rates by leveraging volume discounts and building relationships with shipping partners. Optimizing packaging and shipping strategies reduces costs and improves overall profitability.

Inadequate Returns Management

Inadequate returns management significantly affects customer loyalty, with 85% of online shoppers likely to shop elsewhere after a poor delivery experience. Common challenges include long processing times, unclear return policies, and inefficiencies in restocking, leading to disillusioned clients and increased operational costs.

Confusing return policies and limited options create customer frustration, reducing overall satisfaction with the buying experience. Effective returns management is crucial for sustaining profitability, as highlighted by the high return rates in ecommerce sales.

Implementing clear return policies and efficient restocking processes can enhance customer satisfaction and loyalty.

Scalability Issues

Neglecting scalability in order fulfillment can result in increased inefficiencies and operational errors as a business expands. As businesses grow, inefficiencies and errors can become more pronounced. Investing in scalable systems is critical to maintaining efficiency and accuracy in order fulfillment.

This becomes particularly critical during high-volume seasons, where thanksgiving challenges can overwhelm unprepared fulfillment operations and lead to shipping delays, inventory discrepancies, and damaged customer relationships that persist long after the holiday season ends.

Implementing scalable systems significantly enhances order fulfillment processes and supports business growth. Planning for scalability ensures fulfillment operations remain efficient and effective, even as order volumes increase.

Leveraging Technology for Efficient Order Fulfillment

Leveraging technology in order fulfillment significantly minimizes human errors and improves order accuracy. Automating fulfillment tasks enhances operational efficiency and helps businesses scale effectively. For example, Trans-Matic reduced its receiving time from 3 hours daily to just 20 minutes through enhanced processes.

Many businesses discover that the 3PL advantage extends beyond cost savings to include access to advanced fulfillment technologies and expertise that would be prohibitively expensive to develop in-house, allowing even small companies to offer enterprise-level fulfillment experiences.

Utilizing barcode scanning and RFID technology in warehouses streamlines the order fulfillment process and reduces errors. Real-time visibility into operations, as demonstrated by a leading pharmaceutical manufacturer, improves overall fulfillment efficiency.

Adopting these technological advancements allows businesses to optimize their fulfillment operations and achieve accurate order fulfillment.

Aligning Your Fulfillment Strategy with Business Goals

Integrating order fulfillment processes with business objectives enhances supply chain efficiency and meets customer expectations. Collaboration between departments, such as marketing and logistics, is vital for aligning fulfillment strategies with overarching business goals.

Cloud-based warehouse management systems significantly enhance operational efficiency and flexibility. Implementing advanced analytics improves decision-making through insights derived from operational data. A responsive order fulfillment strategy contributes to better customer satisfaction and loyalty by meeting delivery expectations.

Order Fulfillment Mistakes FAQs

What are the 7 steps of order fulfillment?

The 7 steps of order fulfillment are:

- Receiving inventory

- Storing products

- Processing orders

- Picking items

- Packing orders

- Shipping packages

- Handling returns

These steps ensure efficient order processing, timely delivery, and customer satisfaction.

How do you ensure order accuracy?

Ensure order accuracy by using barcode scanning, automated inventory management, and quality control checks. Implement double-check procedures during picking and packing, train staff on accuracy best practices, and integrate real-time tracking to minimize errors.

What is the initial step in the order fulfillment process?

The initial step in the order fulfillment process is receiving inventory. This involves inspecting, counting, and storing products in the warehouse to ensure accurate stock levels and efficient order processing.

What are the three types of order fulfillment?

The three types of order fulfillment are in-house fulfillment, third-party logistics (3PL), and dropshipping. In-house fulfillment means managing orders internally, 3PL involves outsourcing logistics to a provider, and dropshipping allows suppliers to ship directly to customers.

What is a good order fulfillment rate?

A good order fulfillment rate is 95% or higher. This means at least 95% of orders are processed, shipped, and delivered on time without errors. High fulfillment rates improve customer satisfaction and operational efficiency.

How Innovative Warehouse Solutions, LLC Can Help

Innovative Warehouse Solutions, LLC specializes in warehouse layout storage and logistics solutions, securely storing products and distributing them directly to clients. IWS allows users to upload multiple orders at once via a CSV file for simplicity and ease, alongside providing customizable reports for analyzing business performance.

Through strategic warehousing approaches, IWS optimizes inventory placement, picking paths, and storage utilization to minimize handling time and errors, creating more efficient fulfillment operations that scale with your business growth while maintaining accuracy and speed.