East Coast Fulfillment Services: Full Analysis of Strategic Logistics Solutions

What East Coast Fulfillment Services Cover

East coast fulfillment services encompass comprehensive third-party logistics solutions including warehouse space, inventory management, order fulfillment, and shipping operations. These services handle everything from receiving your products at the warehouse door to ensuring the right stuff reaches your customers safely and quickly.

Unlike basic warehouse storage, modern fulfillment providers offer integrated technology platforms that connect seamlessly with your business systems. This includes real-time inventory tracking, automated order processing, and multi-carrier shipping options that scale with your growing business needs.

The east coast advantage becomes clear when you consider that most businesses lose money on shipping costs without strategic warehouse placement. Professional 3PL partnerships provide immediate access to discounted shipping rates and optimized logistics processes that would take years to develop independently.

Why the East Coast Wins: Population Reach & Cost Advantages

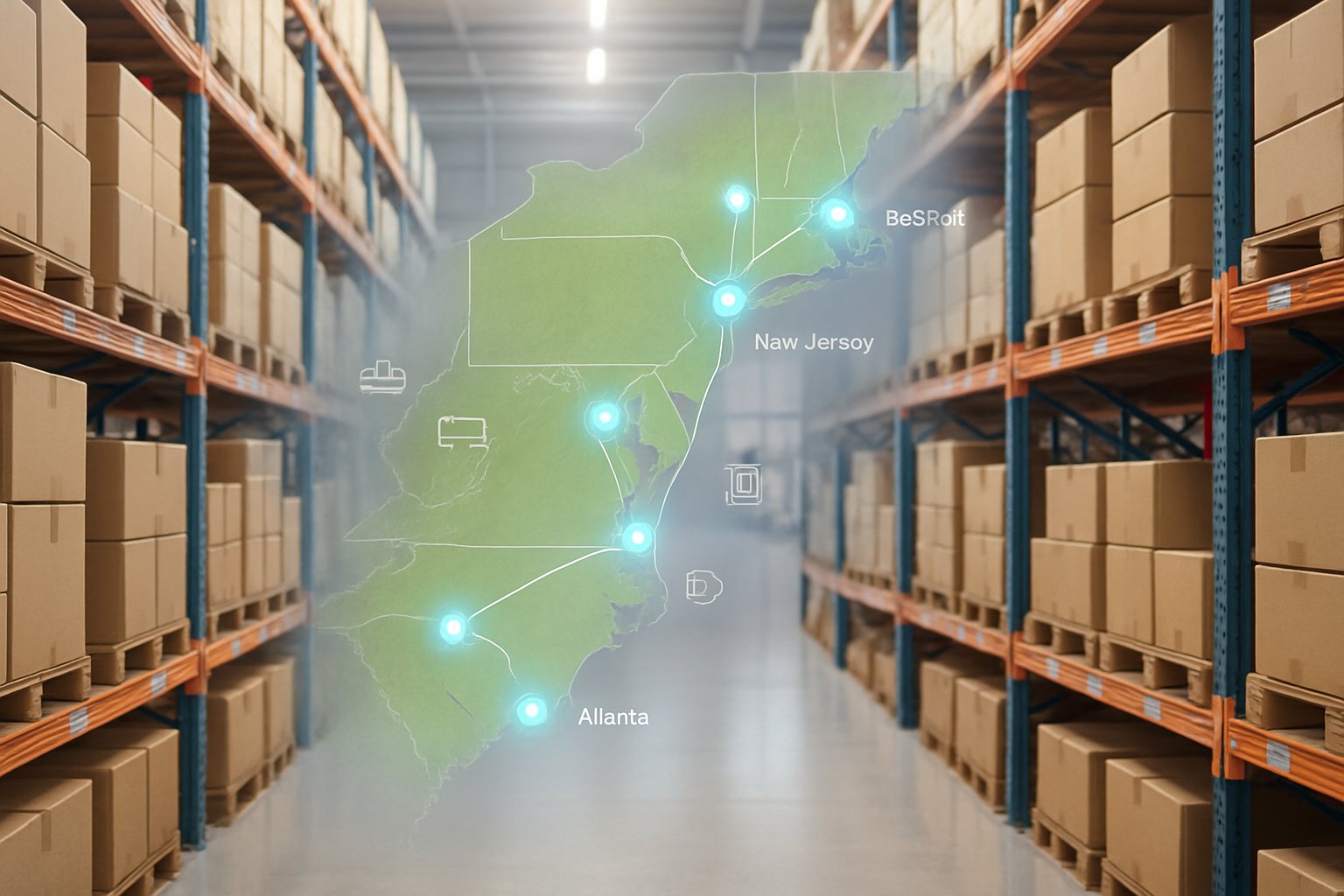

Positioning your inventory on the East Coast means reaching over 180 million customers within 2-day ground shipping zones. This coverage includes major metropolitan areas from Boston to Atlanta, providing access to some of the highest-spending consumer markets without the expense of expedited shipping services.

Port proximity delivers significant advantages for businesses importing products. Major ports in NY/NJ, Norfolk, Charleston, and Savannah handle millions of containers annually, reducing your inbound freight costs by 15-25% compared to alternative locations. This proximity means your products move quickly from port to warehouse, minimizing transit time and reducing damage risk.

When shipping to customers in New York from a New Jersey warehouse versus a California facility, the difference in both cost and delivery speed creates an immediate bottom-line impact. Zone skipping strategies become unnecessary when your inventory starts closer to your customer base.

Major East Coast Fulfillment Hubs (At-a-Glance)

NJ/NY Corridor offers unparalleled access to NYC and Philadelphia markets but comes with higher facility and labor costs. This region works best for businesses prioritizing speed over cost optimization.

Pennsylvania provides balanced coverage for northeastern and midwestern markets with excellent highway and rail connections. Many businesses find this area ideal for serving diverse geographic markets from a single location.

Virginia/North Carolina delivers central southeastern coverage while maintaining cost-efficient operations. This region offers an attractive balance of geographic reach and operational expenses.

Georgia/South Carolina serves as the gateway to southeastern states with excellent international shipping access through Savannah and Charleston ports. This positioning works particularly well for import-heavy brands needing efficient container processing.

Most businesses start with a single node and add a second location only when order volume justifies the complexity. Strategic warehousing decisions should align with your actual shipping patterns rather than theoretical coverage maps.

Core Capabilities & SLAs You Should Expect

B2C Operations: Leading providers guarantee same-day shipping for orders received by 11 AM EST, maintaining 99%+ picking accuracy rates. Multi-carrier options ensure you get the best shipping rates while maintaining the delivery speed your customers expect.

B2B/Wholesale: EDI compliance, retailer-specific routing and labeling, and on-time-in-full (OTIF) performance meet the demanding requirements of retail partners. Professional fulfillment operations understand that B2B relationships depend on consistent compliance and accuracy.

Value-Added Services: Kitting and bundling capabilities, returns processing, quality control, and light assembly work extend your operational capabilities without internal investment. These services prove essential for businesses selling across multiple channels or requiring custom packaging solutions.

The best providers implement zero shrinkage policies, meaning you never lose inventory to warehouse handling errors. This level of care protects your investment while ensuring accurate stock levels across all sales channels.

Technology Stack & Integrations

Real-time inventory management systems provide 24/7 visibility into your stock levels, preventing overselling while optimizing reorder timing. Advanced software platforms automatically sync inventory across all sales channels, ensuring accurate availability regardless of where customers shop.

Essential integrations include Shopify, Amazon, WooCommerce, and BigCommerce connections that import orders automatically and update tracking information without manual intervention. Comprehensive integration capabilities eliminate the need for manual data entry while reducing order processing errors.

Order management features should include backorder handling, inventory allocation rules, and exception management that keeps your business running smoothly. API connectivity allows custom integrations with accounting systems, customer service platforms, and business intelligence tools.

Pricing Models & Benchmark KPIs

Storage costs typically range from $0.50-$8.75 per week depending on space requirements, with pick fees varying based on order volume and complexity. Transparent pricing models eliminate hidden fees while providing predictable cost structures that scale with your business growth.

Key performance indicators to negotiate include 99%+ picking accuracy, same-day ship rates for standard orders, and dock-to-stock timeframes under 24 hours. Cycle count accuracy above 99.5% ensures your inventory records remain reliable for business planning.

Compare quotes by evaluating total cost per order rather than individual line items. The lowest storage rate means nothing if pick fees, packaging costs, or shipping rates offset those savings.

Provider Selection Checklist

Evaluate providers based on your specific product profile, order patterns, and channel mix rather than generic capabilities. A provider excellent for apparel may lack the expertise needed for health and beauty logistics or fragile product handling.

Facility location should align with your order heat map, not theoretical coverage areas. Request references from businesses with similar products and order volumes to understand real-world performance rather than marketing promises.

Contract flexibility becomes crucial as your business grows. Avoiding common fulfillment mistakes starts with choosing partners who adapt to changing needs rather than forcing rigid operational requirements.

Implementation Playbook

Discovery Phase: Data mapping and integration planning ensure smooth system connections and accurate inventory transfer. This phase identifies potential challenges before they impact customer orders.

Integration and Testing: User acceptance testing (UAT) validates that all systems work correctly before processing live orders. Pilot programs with limited SKUs or order types allow optimization without risking customer satisfaction.

Controlled Ramp: Gradual volume increases ensure quality maintenance while building operational confidence. Professional implementation processes include detailed success metrics for week 1, 30, and 90 performance evaluation.

Inventory transfer requires careful planning to maintain stock availability during transition. The best providers coordinate timing to prevent stockouts while ensuring accurate receiving and slotting processes.

Risk & Mitigation Plan

Labor seasonality affects all fulfillment operations, particularly during peak shipping periods. Successful providers maintain flexible staffing arrangements and automation where it delivers measurable benefits without compromising service quality.

Urban last-mile challenges require carrier diversification and alternative delivery options. Smart parcel management includes consolidated shipping options and local delivery partnerships that improve customer experience.

Weather contingencies and space constraints demand proactive planning rather than reactive responses. Providers with owned facilities and established backup procedures maintain operations even during challenging conditions.

Trends That Actually Affect Your Operations

Practical automation focuses on picking accuracy and speed improvements rather than wholesale job replacement. Robotic systems augment human capabilities while maintaining the flexibility needed for diverse product handling.

Micro-fulfillment centers enable same-day delivery for fast-moving SKUs in dense urban markets. This trend affects businesses selling time-sensitive products or competing on delivery speed rather than just cost.

Demand forecasting integration helps optimize inventory levels while reducing carrying costs. Cross-docking capabilities become more valuable as businesses seek to minimize inventory investment while maintaining availability.

FAQs

What areas can East Coast fulfillment centers reach within 2 days?

Most East Coast facilities reach shipping zones 1-4 within 2 business days, covering approximately 60% of the U.S. population, including major metropolitan areas from Boston to Atlanta and extending west to Chicago.

How do East Coast fulfillment costs compare to West Coast alternatives?

East coast positioning typically offers 15-25% lower inbound freight costs due to port proximity, while outbound shipping costs are 10-20% lower when serving eastern U.S. customers compared to west coast distribution.

What minimum order volumes do providers typically require?

Professional East Coast providers accommodate businesses starting at 100-500 orders per month, with scalable pricing that grows with your business without requiring long-term volume commitments.

How long does implementation take?

Standard implementation timelines range from 2-6 weeks, depending on inventory complexity and integration requirements, with rush implementations possible in 7-14 days for urgent business needs.

Innovative Warehouse Solutions: What Sets Us Apart

Dedicated account management ensures your business receives personalized attention rather than generic service. Our team understands that your success depends on having the right stuff delivered to the right place at the right time, every time.

Transparent SLAs eliminate surprises while providing predictable performance you can build your business around. Zero shrinkage policies protect your inventory investment, ensuring accurate stock levels and eliminating unexpected losses.

Port-proximate facilities in key east coast locations provide optimal shipping access while maintaining cost-effective operations. Our proven approach combines geographic advantages with operational excellence that scales with your growing business.

Ready to optimize your fulfillment operations with strategic East Coast positioning? Contact our team today to discuss how our warehouse solutions can support your business growth while ensuring customer satisfaction through accurate, on-time shipments.